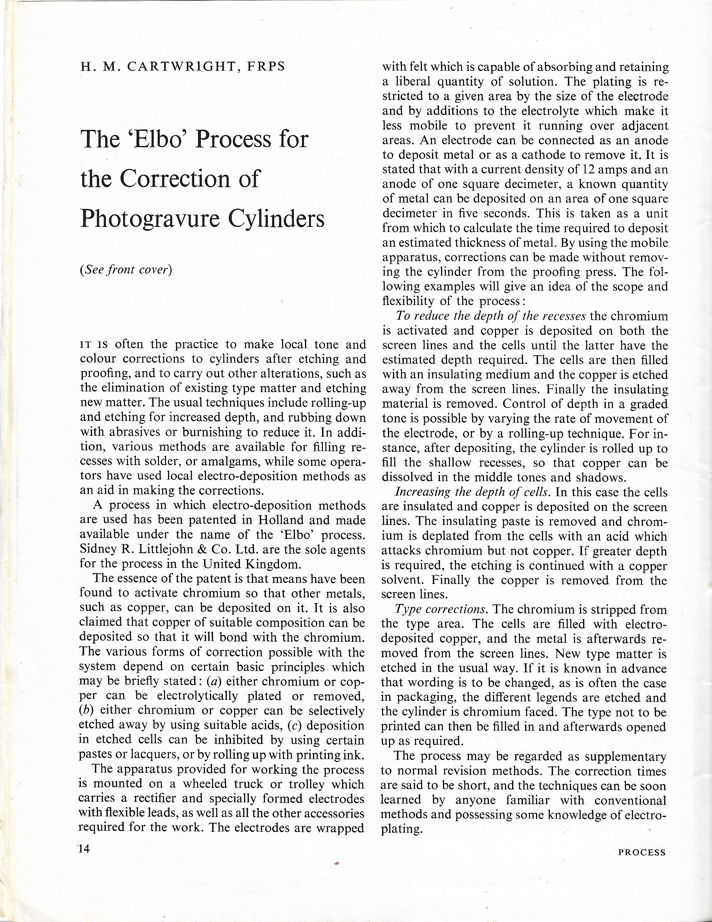

The Elbo Process for the correction of Photogravure Cylinder

Uit het engelse vaktijdschrift "Process" Januari 1957.

IT is often the practice to make local tone and colour corrections to cylinders after etching and proofing, and to carry out other alterations,

such as the elimination of existing type matter and etching new matter. The usual techniques include rolling-up and etching for increased depth,

and rubbing down with abrasives or burnishing to reduce it. In addi- tion, various methods are available for filling re- cesses with solder, or amalgams,

while some opera- tors have used local electro-deposition methods as an aid in making the corrections. A process in which electro-deposition

methods are used has been patented in Holland and made available under the name of the "Elbo" process. Sidney R. Littlejohn & Co. Ltd. are the sole agents

for the process in the United Kingdom.

The essence of the patent is that means have been found to activate chromium so that other metals, such as copper, can be deposited on it.

It is also claimed that copper of suitable composition can be deposited so that it will bond with the chromium. The various forms of correction possible

with the system depend on certain basic principles which may be briefly stated: (a) either chromium or cop- per can be electrolytically plated or removed,

(6) either chromium or copper can be selectively etched away by using suitable acids, (c) deposition in etched cells can be inhibited by using certain

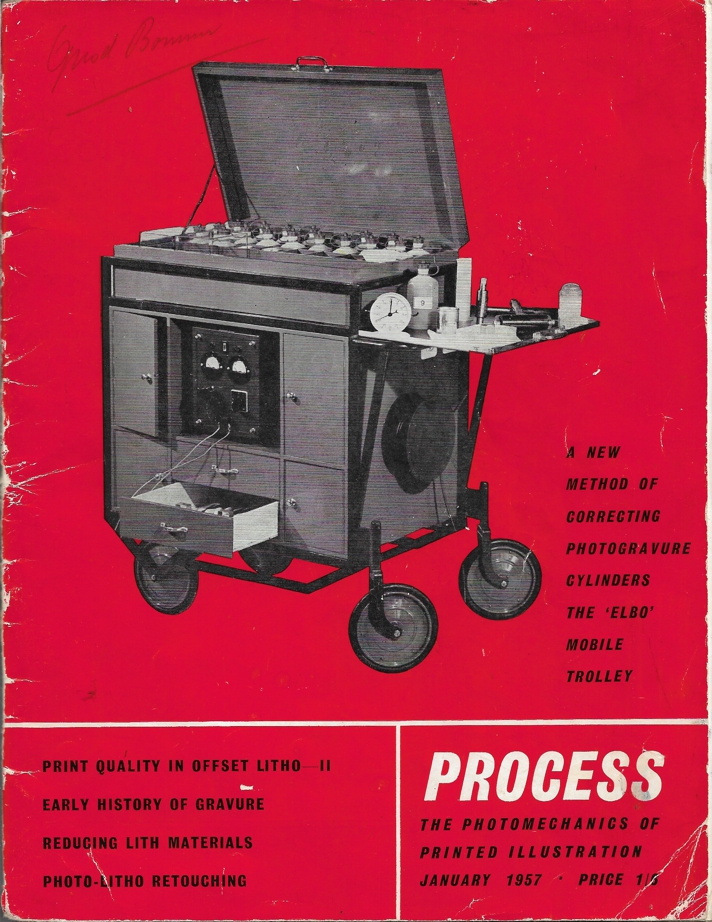

pastes or lacquers, or by rolling up with printing ink. The apparatus provided for working the process is mounted on a wheeled truck or trolley which

carries a rectifier and specially formed clectrodes with flexible leads, as well as all the other accessories required for the work. The electrodes are wrapped

with felt which is capable of absorbing and retaining a liberal quantity of solution. The plating is restricted to a given area by the size of the electrode

and by additions to the electrolyte which make it less mobile to prevent it running over adjacent areas. An electrode can he connected as an anode to deposit metal

or as a cathode to remove it.

1 is stated that with a current density of 12 amps and an anode of one square decimeter, a known quantity of metal can be deposited on an area of one

square decimeter in five seconds. This is taken as a unit from which to calculate the time required 10 deposit an estimated thickness of metal.

By using the mobile apparatus, corrections can be made without remov- ing the cylinder from the proofing press. The fol- lowing examples will give an idea of the

scope and flexibility of the process: To reduce the depth of the recesses the chromium is activated and copper is deposited on both the screen lines and

the cells until the latter have the estimated depth required. The cells are then filled with an insulating medium and the copper is etched away from the screen lines.

Finally the insulating material is removed. Control of depth in a graded tone is possible by varying the rate of movement of the electrode, or by a rolling-up technique.

For in- stance, after depositing, the cylinder is rolled up to fill the shallow recesses, so that copper can be dissolved in the middle tones and shadows.

Increasing the depth of cells. In this case the cells are insulated and copper is deposited on the screen lines. The insulating paste is removed and chrom- ium is

deplated from the cells with an acid which attacks chromium but not copper. If greater depth is required, the etching is continued with a copper solvent.

Finally the copper is removed from the screen lines. Type corrections. The chromium is stripped from the type area. The cells are filled with electro- deposited copper,

and the metal is afterwards re- moved from the screen lines. New type matter is etched in the usual way. If it is known in advance that wording is to be changed, as is often

the case in packaging, the different legends are etched and the cylinder is chromium faced. The type not to be printed can then be filled in and afterwards opened up as required.

The process may be regarded as supplementary to normal revision methods. The correction times are said to be short, and the techniques can be soon

learned by anyone familiar with conventional methods and possessing some knowledge of electroplating.